PFW6.2

PFW6.2

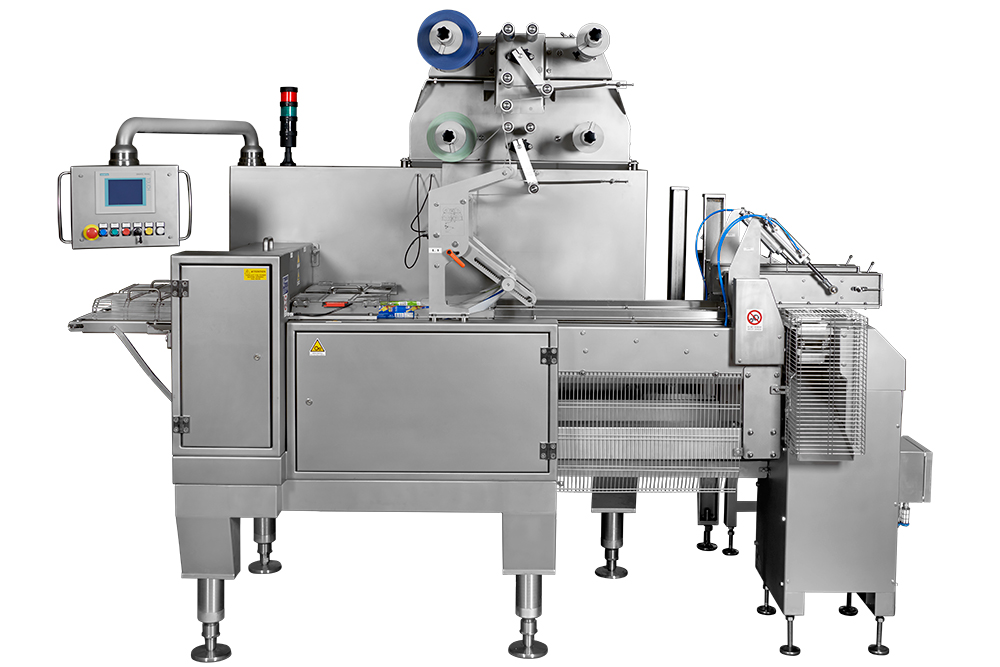

PFW6.2 horizontal form fill and seal machine is a multi lane flow wrap, with two stand-alone or synchronized infeed conveyors. Its compact design and easy to use interface and setting lead to substantial savings in term of surface required and control operators. Furthermore low linear speed provides an higher degree of packaging efficiency.

This machine is the ideal solution for those industries characterized by high production output and continuous change of shape or product type or limited factory space.

The main features of this machine are:

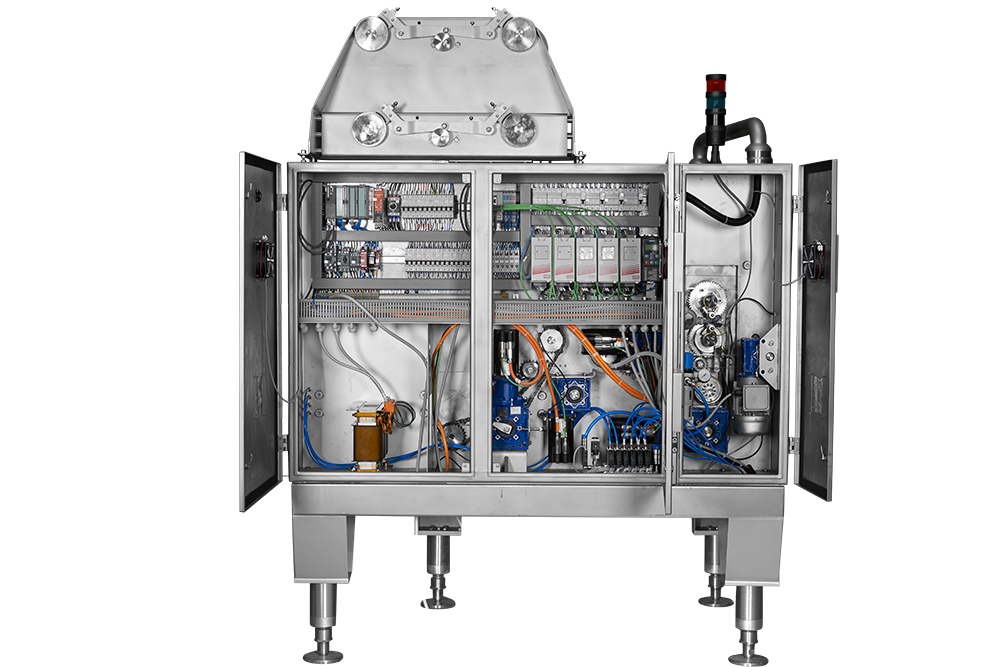

- Compact construction in AISI304 stainless steel with built-in electric cabinet.

- Fully servo-assisted machine.

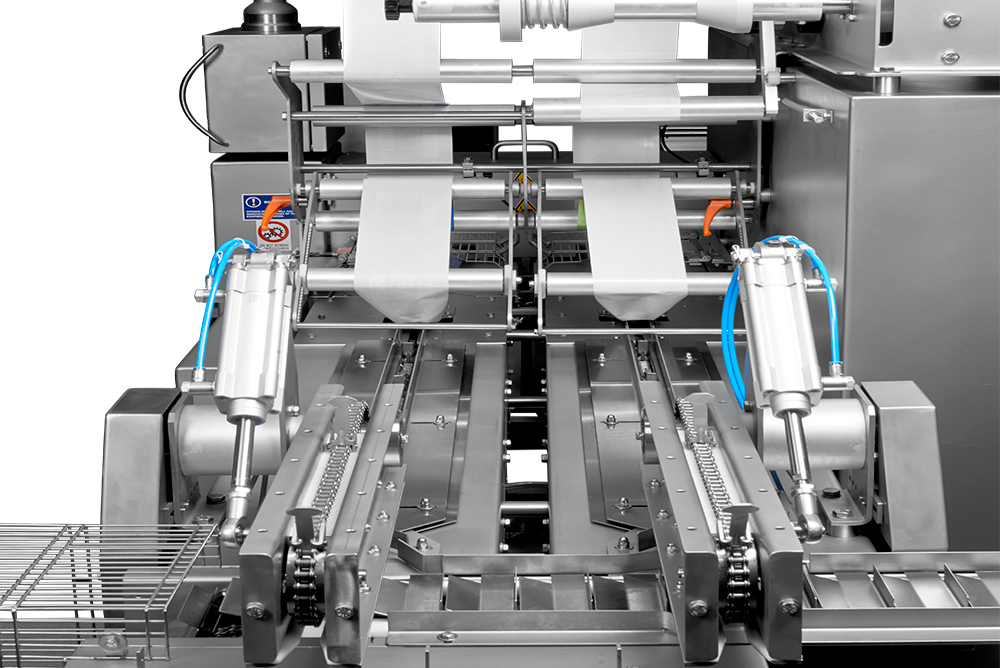

- Two or three couple of sealing rollers with temperature control and product length managed via PLC.

- Double rotary jaws group per line with a standard width of 150mm.

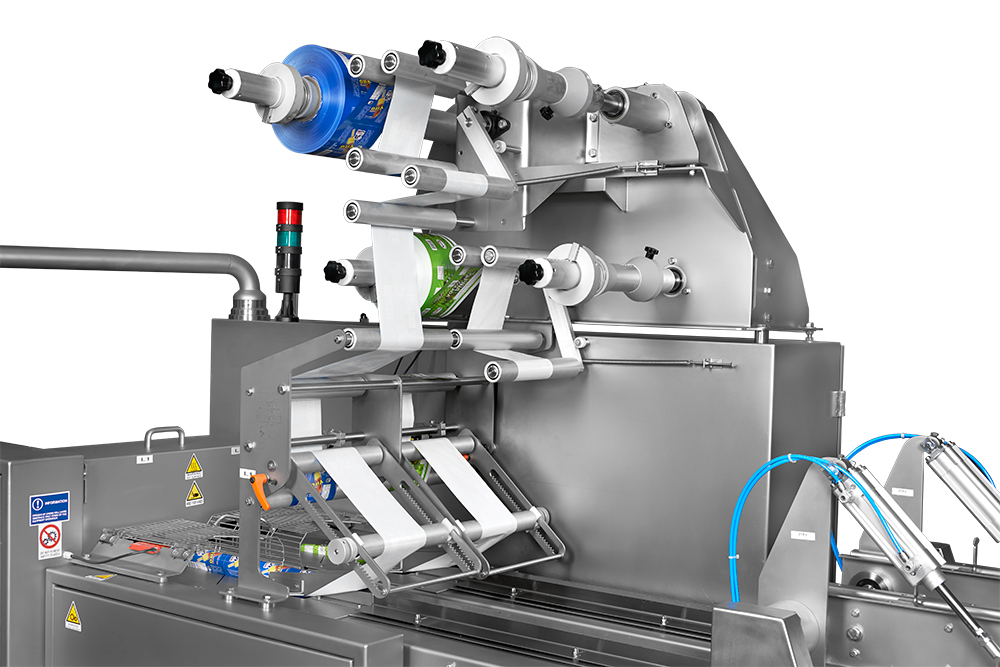

- Double reel holder with self centering cones and electric eye.

- FESTO pneumatic components and Siemens electronic devices integrated in the rear part of the machine.

Machine speed: up to 400 ppm. Machine speed depends on the product

Product dimensions: up to 300x100x60mm**

Reel specifications: up to L=300mm – Øi=85mm – Øe=300mm – Max weight=35kg**

Power requirements: power supply from 220 to 460 V – Frequency 50/60 Hz

Pneumatic group: 6 bar compressed air

Machine dimensions: 2750X850X1720mm – Weight: approx. 750kg

Machine dimensions could change in order to fit the need of our customers

Infeed conveyor: Length: 1500mm – Working level: 1000mm**

Sealing rollers: Standard sealing: 15mm**

Sealing jaws: Standard jaw width: 150mm – Linear or zig-zag blade

**Custom made solutions available upon request.

- Mechanical barret transfer

- Vacuum generation system

- Mechanical or pneumatic gusset system

- Automatic reel holder

- Adjustable folding box

- Coding or tracking devices

- No product no bag

- Other options upon request